Home > Product > Electric Heater

PRODUCT

Electric Heater

Create Customer value through innovative system Engineering

-

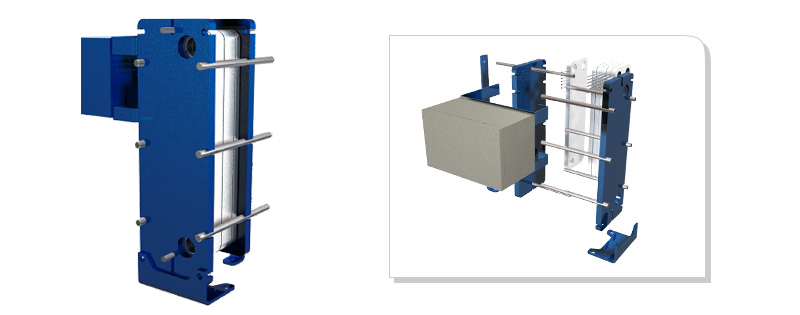

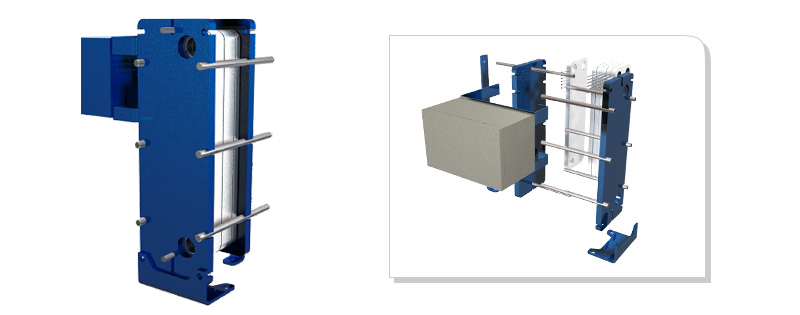

Electric Plate Heater

Electric Plate Heater

-

MnSi ELPHE has been developed to overcome shortcomings of the conventional shell & tube heat exchanger – high

efficiency with miniaturization. It is capable of heating by 15KW per one electric aluminum plate with high thermo

convective.

- Compact design and safety control.

- In addition to the control and protection on piping line, Safety system is functioned by backup of

thermal couple directly inserted into the inside of electric plate.

- As ELPHE is designed with fully enclosed structure, no leakage and explosion can be assured even in

abnormal condition. On the contrary, invasion of the external explosive gas can be prevented by

openings

and surfaces(EX II B T4 Approved and ertified).

- ELPHE is patented under MnSi.

- Diesel engine fuel oil/Diesel engine, turbine and compressor lubricating oil/Miller, driller and

lathe cutting oil/Chemical process/Sea water, raw water etc in Power and Marine Application.

Specification

| Body |

| Material |

SS400 or Equirevalriant ASTM |

| Connection |

DIN, ANSI, JIS, KS over all STD |

| Volume Flow |

Max. 15m³ / h |

| Weight / Dimension |

75kg / 800 x 300 x 650 |

| Electric Plate |

| Material |

AC4C or Equirevalriant ASTM |

| Heat Transfer Area |

0.22 m² |

| Power Capacity |

15kW / 480V |

| Heating Element |

Silicon Coated Magnesia |

| Application |

Lub. Oil, Fuel Oil, Water, Etc., |

| Operating Temperature |

-10°C ~ 160°C |

| Working / Test Pressure |

16 bar / 24 bar |

| Juction Box |

| Material |

SS400 or Equirevalriant ASTM |

| Paint |

RAL 7032 |

| Cable Grand |

PG25 / 35 |

| Model |

Max. Temp. / Press. |

Max. Operating Power |

Dimension |

Connections |

| ELPHE02 |

180°C / 16 bar |

45kW(9 Block) |

350(h) x 105(w)mm |

25A |

| ELPHE08 |

180°C / 16 bar |

225kW(15 Block) |

640(h) x 187(w) mm |

50A |

- Compact design and safety control.

- In addition to the control and protection on piping line, Safety system is functioned by backup of

thermal couple directly inserted into the inside of electric plate.

- As ELPHE is designed with fully enclosed structure, no leakage and explosion can be assured even in

abnormal condition. On the contrary, invasion of the external explosive gas can be prevented by

openings

and surfaces(EX II B T4 Approved and ertified).

- ELPHE is patented under MnSi.

- Diesel engine fuel oil/Diesel engine, turbine and compressor lubricating oil/Miller, driller and

lathe cutting oil/Chemical process/Sea water, raw water etc in Power and Marine Application.

Specification

| Body |

| Material |

SS400 or Equirevalriant ASTM |

| Connection |

MNSI Special 25A |

| Volume Flow |

Max. 15m³ / h |

| Weight / Dimension |

40kg / 600 x 300 x 200 |

| Electric Plate |

| Material |

AC4C or Equirevalriant ASTM |

| Heat Transfer Area |

0.18m² |

| Power Capacity |

5kW / 440V |

| Heating Element |

Silicon coated magnesia |

| Application |

Lub. Oil, Fuel Oil, Water, Etc., |

| Operating Temperature |

-10°C ~ 160°C |

| Working / Test Pressure |

16 bar / 24 bar |

| Juction Box |

| Material |

SS400 or Equirevalriant ASTM |

| Paint |

RAL 7032 |

| Cable Grand |

PG25 / 35 |

| Model |

Max. Temp. / Press. |

Max. Operating Power |

Number of Blocks |

Connections |

| ELBLK |

180°C / 16 bar |

150kW |

Min. 3 ~ Max. 30 |

SQUARE 25A / 50A |

Home > Product > Electric Heater

Home > Product > Electric Heater

Electric Plate Heater

Electric Plate Heater